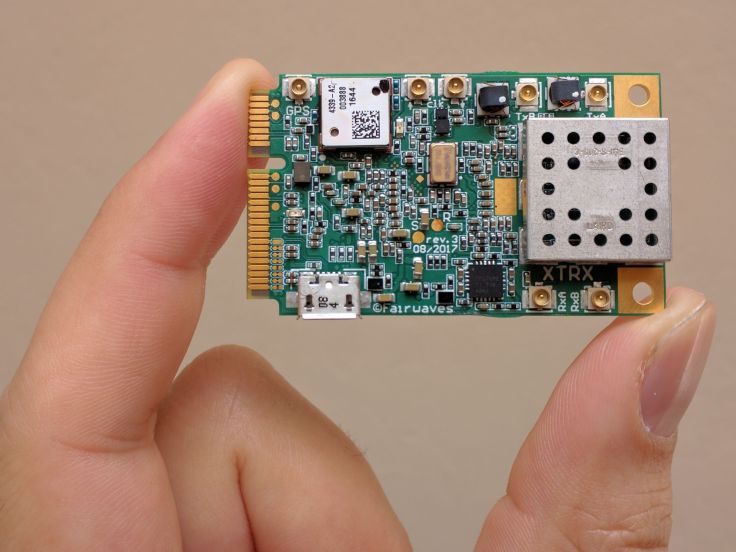

XTRX is a tiny yet high-performance Software Defined Radio (SDR).

THIS SITE IS TEMPORARILY ON HOLD. PLEASE FOLLOW FURTHER UPDATES ON OUR CROWDSUPPLY PRE-LAUNCH PAGE: https://www.crowdsupply.com/fairwaves/xtrx

Most important posts about XTRX:

- Tech specs for the XTRX

- MIMO and independent receive/transmit

- XTRX pinout

- XTRX pinout FAQ

- 33с3 Talk: Lessons learnt in building a low latency, high throughput PCIe based SDR